Biochar for Commercial Horticulture

Less Chemistry More Biology

Innovative biochar blends from Carbon Gold are helping commercial propagators to produce outstanding fruit and vegetables in a variety of systems.

Benefits of Biochar for Commercial Growers

Improves plant health

Increases crop yield

Lowers irrigation costs

Reduces severity of diseases

Commercial growers use our Soil Improver and Biology Blend products enriched with species of mycorrhizal fungi, actinomyces bacteria and trace elements to help raise plants with quicker establishment and root growth, with increased vitality which require less irrigation and nutrient.

Enriched biochar has proven to create abundant flowering and less vegetative leaf, resulting in increased microbial populations in the soil or growing medium and reduced losses.

Both organic and conventional growers use our Soil Improver and Biology Blend to increase cropping, reduce inputs and improve soil health without the use of synthetic chemical nutrients and fungicides.

Get Trade PriceCommercial Grower Case Studies

1 acre, 2000 trees, 0 losses

Intensive orchard production comes with its overheads, and one of the most predictable is loss. But when a grower used Carbon Gold’s Tree Soil Improver which is enriched biochar as planting aid in January 2018…

Read More

What is Biochar's pH and its effects on contaminated soil?

Over the years there have been a number of studies into the effect biochar has on contaminated soil and how biochar can help with remediation in respect of heavy metals such as cadmium, lead and…

Read MoreWhat's in our Enriched Biochar

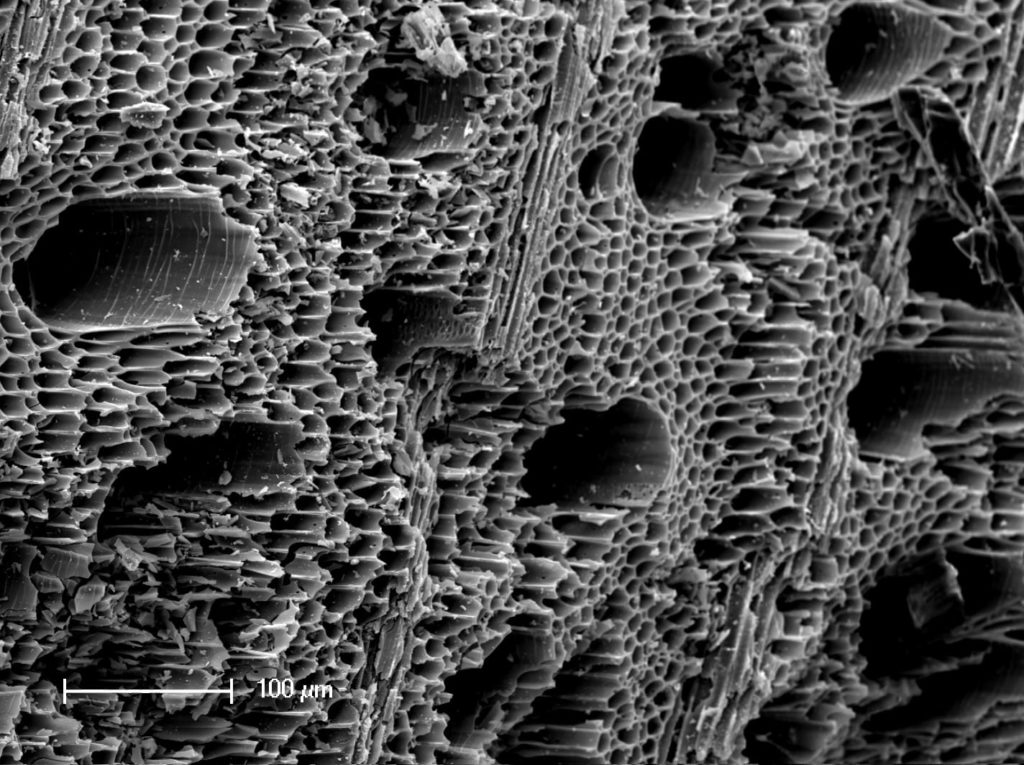

Biochar

A stable form of soil carbon with a naturally porous structure which improves aeration, water-holding capacity and nutrient retention of soils and acts as a refuge for beneficial soil microbiology. The building block of resilient soils.

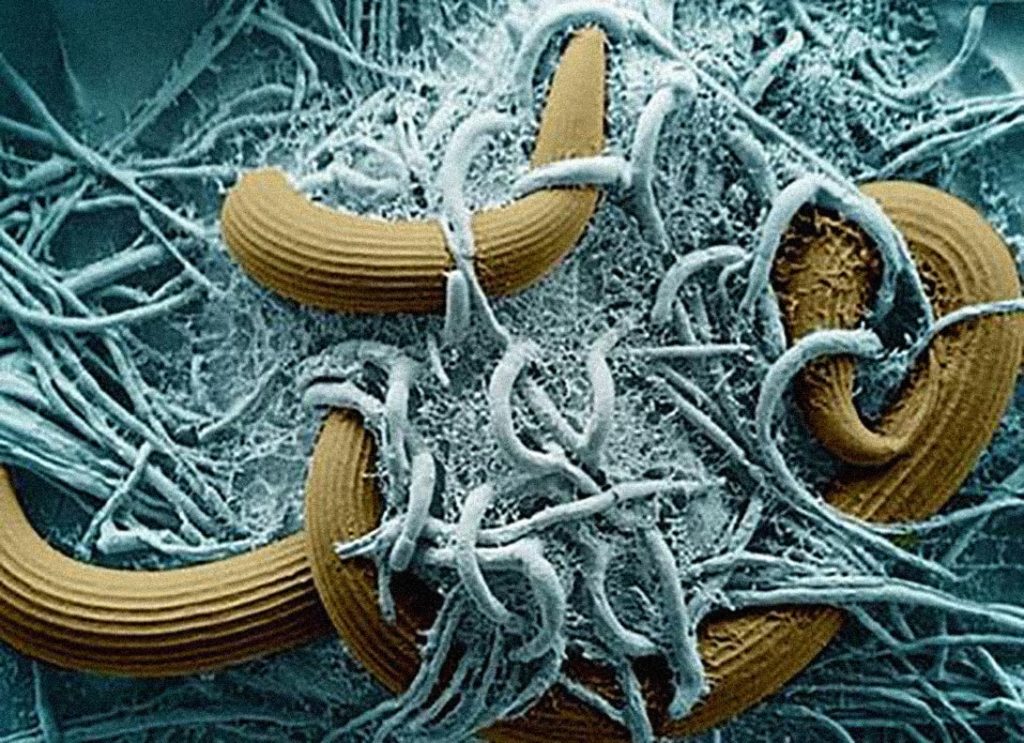

Mycorrhizal Fungi

A natural soil fungi that form a symbiotic partnership with plants, acting as a secondary root system while using the biochar as a refuge.

Trichoderma

An antagonistic type of fungi that feed on soilborne pests, in defence of their host plant's root system, housed inside the biochar.

Seaweed

Filled with trace minerals that are good for healthy plant stems and leaves.

Wormcasts

Full of all the healthy bacteria and humic compounds that roots need to stay healthy.

Request a no-obligation trade price

Get a trade price

Biochar for Sports Turf

From Ascot Racecourse to Premier League football pitches, biochar is a permanent solution for attractive, resilient and playable turf.

More Info

Biochar for Professional Tree Care

When added to top soil and planting media, biochar significantly increases survival rates of newly planted trees, boost the health and vitality of established trees, and reduce losses.

More Info